X-Ray inspection

TMH-novatecYour part 145 MROMore about TMH-novatec

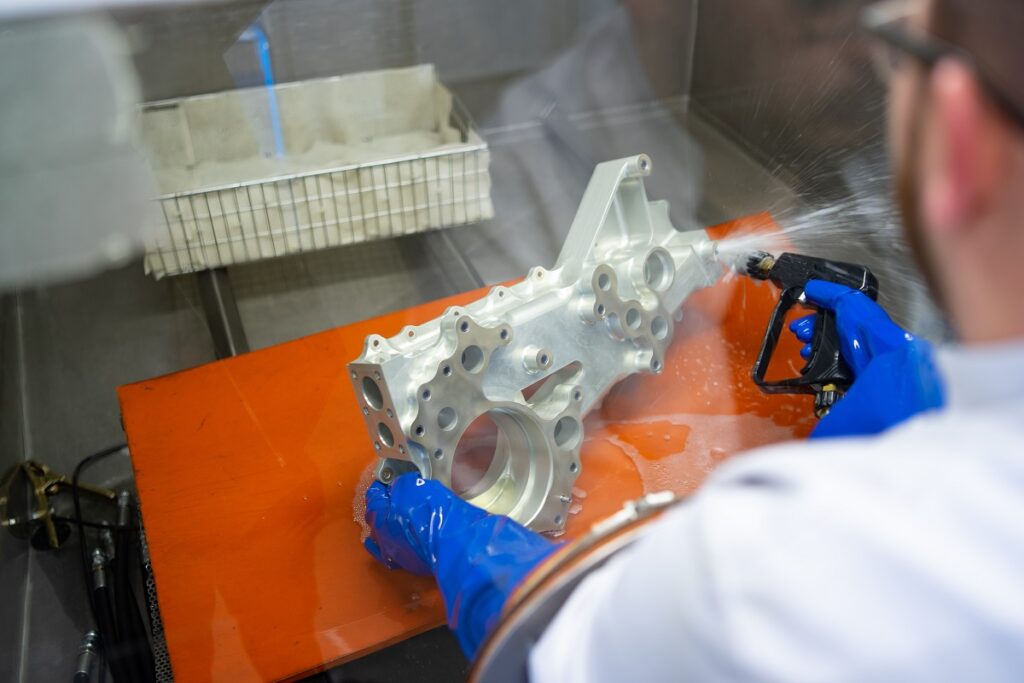

The precision cleaning process is a fine cleaning process that is carried out by using a 3 µm onsite filtered fluid. Particle removal is performed on the mechanical parts of aircraft and helicopter fuel circuits and hydraulic systems. It contributes to the operational reliability of power transmission housings, fuel injectors, hydraulic blocks, pipes, etc.

The goal of the fine cleaning operation is to remove the casting residues (sand from binder), grease, machining chips and other particles, in order to avoid:

The cleaning process uses a combination of three principles:

TMH-Novatec’s knowhow and expertise in particle removal have been recognized for many years now.

We have a dedicated room for the cleaning bench and an ultrasound cleaning bath that are both compliant with aeronautic and general industry standards (ISO standard or customer qualification).

The dimensions of our cleaning device are 1500 mm x 1500 mm x 1000, which makes it possible to process a wide range of component and unit sizes.

This particle removal bench ensures a fine high-pressure (40 to 50 bars) and low-pressure (5 to 7 bars) cleaning, by using a spray gun, a hose with specific tooling, or by syringing. The minimum flow rate is 1000 L/h. The bench is equipped with three hydraulic units that can operate simultaneously or independently.

The dimensions of our ultrasound cleaning bath are 500 mm x 500 mm x 400 mm.

The results of the particle removal process are checked using a cleanliness inspection method in accordance with different methods:

The checking methods and frequency are defined while completing the first article process with our customer. The checking of the results guarantees the cleanliness level is compliant with the required cleanliness class (as defined by the ISO standard or by the customer).

We take great care with the packaging and the protection of the parts. They are packed in PE or VCI bags, with or without a protection fluid, according to the material.

Our installation has been qualified by our aeronautics customers, such as Safran Power Units, Safran Helicopter Engines, Safran Power Units and Safran Transmission Systems.

Our qualifications :

The subcontractors of the companies mentioned above trust us with the particle removal process of the final steps of their production process, just prior to sending the parts to the end customer.

X-Ray inspection

TMH-novatecYour part 145 MROMore about TMH-novatec

Fluorescent Penetrant Inspection (FPI)

Fluorescent Penetrant Inspection (FPI)

TMH-novatecYour Part 145 MROdecouvrir TMH-novatec

Aeronautical painting

TMH-novatecYour part 145 MROMore about TMH-novatec